A global healthcare company, recognized for its innovation in diagnostics and medical devices, approached Wright Engineered Plastics, a Seaway Plastics company, to address production challenges in one of their essential…

This unique project required Wright’s expertise in clean room injection molding to provide noticeable upgrades to product quality for a spinal implant company. Wright Engineered Plastics partnered with an OEM…

Since 1998, this aerospace company has created airplane parts integral to developing a professional and safe interior for global air travelers. Their desire to seek new technologies and design solutions…

The precision industrial electronics company referenced in this case study has spent years developing unique devices related to complex three-dimensional measurement applications, detailed imaging, and supplemental realization solutions. The advanced…

The specific defense contractor discussed in this case study has been an integral provider of premium products to defense companies nationally and internationally since its inception in 1969. With over…

This specific chemical sensor manufacturer has been making air sampling, gas detection, and environment monitoring systems since 1983 and approached Seaway Plastics for their expertise in small-quantity injection molding. Also…

This detection device company has created thousands of different kinds of mass spectrometry devices since its inception in 2012. Many people in many different sectors of law enforcement have used…

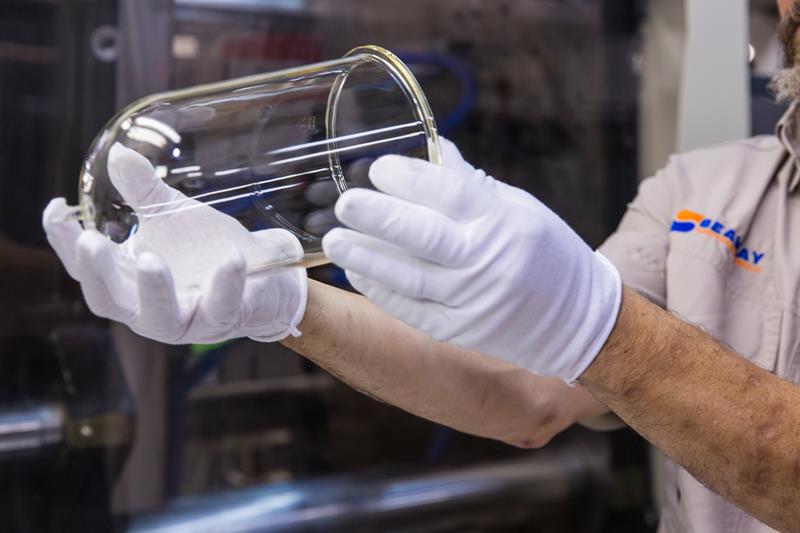

This case study details the partnership built between Seaway Plastics and a unique healthcare company that demanded an experienced ISO 13485-certified medical injection molding company. This healthcare company has provided…