The seaway advantage

Seaway Plastics Engineering has 5 facilities across 3 states and over 250,000 square feet of manufacturing and distribution space. We offer our customers a path for risk mitigation and supply continuity.

- In-House Tooling Design and Build

- DFM Services

- Prototyping to Production

- New Product Introduction and Tooling Transfers

- Extensive Post Molding Operations

All of our facilities are ISO-13485 certified and offer complete quality process validation services. They are also NADCAP accredited for chemical processing and meet the strict US standards for ITAR registration.

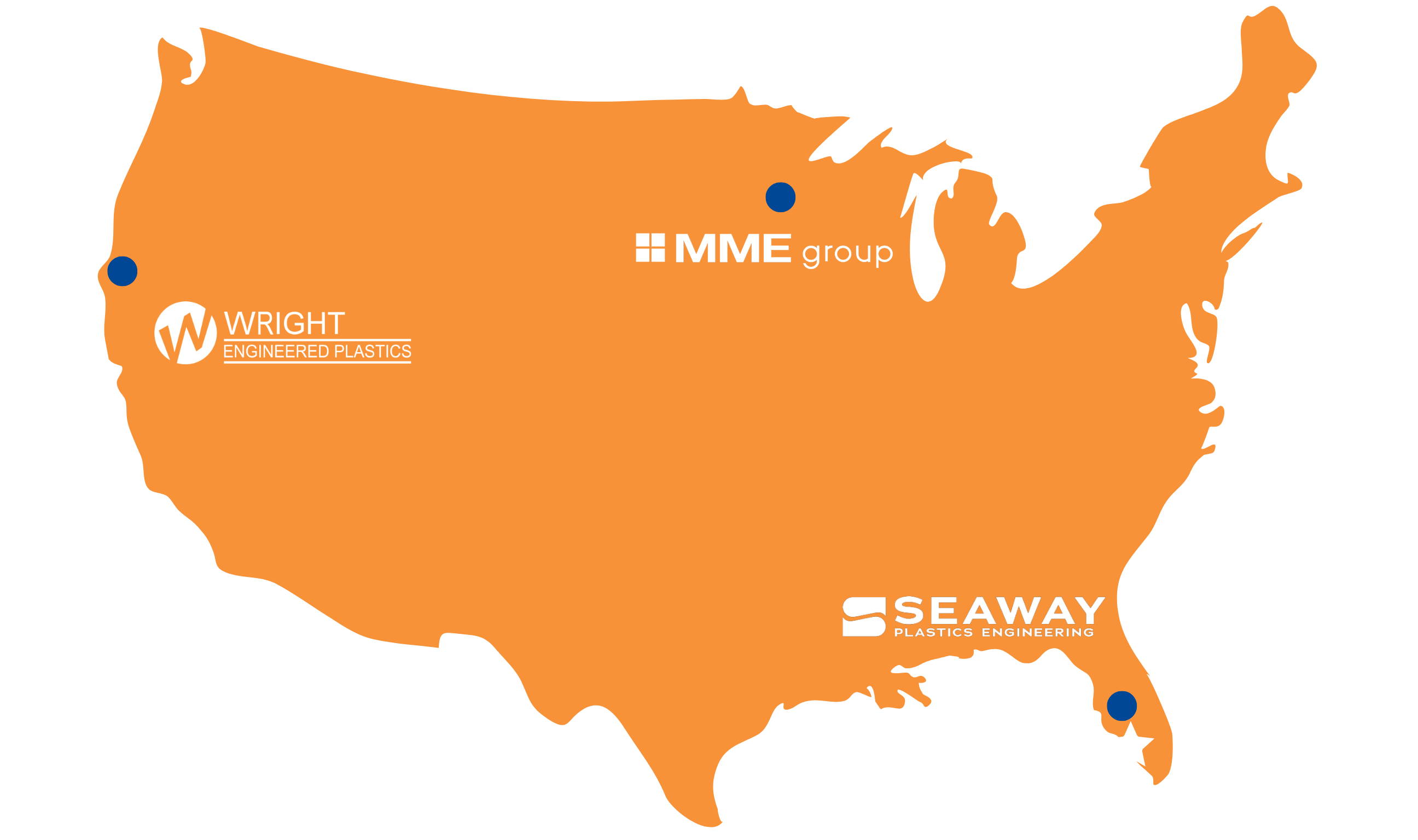

SEAWAY PLASTICS ENGINEERING HEADQUARTERS IN PORT RICHEY, FL

With over 120 full-time employees making tools and products in-house, the Port Richey facility serves national and international clients who need prototyping, low-volume injection molding, and design services. Also at this facility, customers get direct access to Seaway’s administrative, engineering, production, and design teams.

Facility capabilities include:

- Low volume plastic injection molding

- Extensive Tooling and Molding Resources

- Prototyping

- DFM and Engineering Services

- Specialized Post Production Services

- ISO-13485 & ITAR Registered

- ISO 9001 & NADCAP Accredited

SEAWAY PLASTICS ENGINEERING IN BROOKSVILLE, FL

Brooksville focuses on mid to high-volume production. It also has the capacity to handle the production, post-production, and inspection of over 1 million parts per year for highly regulated industries.

Facility capabilities include:

- Tooling and molding resources for mid to high-volume injection molding

- Insert Molding

- Over Molding

- Post-production services including custom packaging

- ISO-13485 & ITAR Registered

- FDA Registered, ISO 9001 & NADCAP Accredited

MME Group in St. Paul, MN

MME was acquired by Seaway in 2022. Their facilities boast over 20,000 square feet of custom-built Class 8 hard wall clean rooms, which include plastic and LSR molding space, and Class 7 hard wall clean rooms for assembly operations. MME specializes in the medical, highly regulated and consumer industries.

Facility capabilities include:

- DFM & Engineering

- Tooling Design & Build

- Plastic and Silicone Injection Molding

- ISO Class 7 & 8 Clean Rooms

- Secondary Operations, Full Assemblies

- Custom Validation & Qualification Packages

- Kitting, Packaging & Distribution Services

- ISO-13485 & ITAR Registered

- FDA Registered, UL, CE, TUV Products, FMR Registered

WRIGHT ENGINEERED PLASTICS IN SANTA ROSA, CA

Acquired by Seaway in 2020, Wright Engineered Plastics handles low to high-volume orders. This facility specializes in lean manufacturing and automation, and our highly experienced and well-trained staff are committed to providing the highest quality products and service.

Facility capabilities include:

- Fully automated robotic systems and machines

- Over Molding

- ISO Class 7 & 8 Clean Rooms

- Sterile Kit Packaging

- Certified Green Business

- California Food & Drug Branch Registration

- ISO-13485 & ITAR Compliant

- FDA Registered