About Wright

Wright is located in Santa Rosa, CA. We serve a diverse clientele, working with both startups and established medical device manufacturers. Our commitment to quality plastic manufacturing makes us a reliable partner in the industry.

Highlighted Offerings

Low to High Volume Capabilities

Cleanroom Molding & Assembly

Post Molding Operations

New Product Development through Commercialization

Molding Capabilities

- Cleanroom molding and assembly

- Press range from 30 ton to 385 ton

- Insert molding

- Over-molding

- Vertical press molding

- Turnkey manufacturing and product assembly

Contract Manufacturing & Secondary Operations

- ESD protection including shielding applications

- Clean room assembly - ISO Class 7 & 8 certified

- Assembly cells incorporated with molding presses

- Custom machining services

- Full secondary applications including:

- pad printing (multi color)

- heat staking

- leak testing

- sonic welding

- thermal/ultrasonic inserting

- ultrasonic cleaning

- electrical testing

- post molding machining

- CNC machining

- painting and shielding management services

- pressure and vacuum testing

- automated screwing systems

- custom labeling

- Effective procurement and supply chain management

Highly Engineered Thermoplastic Materials

Wright uses its molding expertise to create custom solutions to the most challenging manufacturing problems.

For example, using special tooling techniques for insert molding, Wright manufactures plastic parts that create a hermetic seal so they can be assembled without extra chemicals or adhesives. Additionally, Wright’s innovative in-mold process assembles plastic parts with other components inside the mold itself. This creates a complete product the moment the plastic cools, while also reducing the need for chemicals and the potential for human error.

- Ultem

- PEEK

- LCP

- Polycarbonate

- ABS

- PPS

- PEI

- Isoplast

- Many other types of elastomers

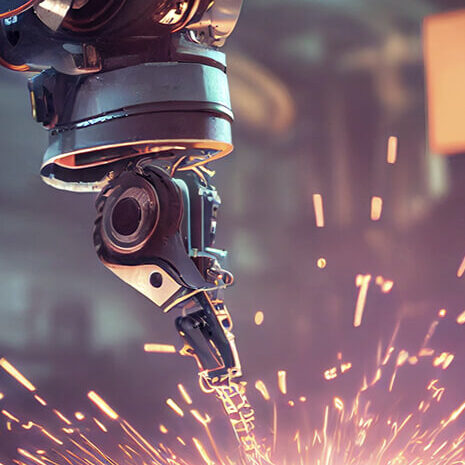

To improve reliability, reduce costs, and create functional differentiation, Wright constantly embraces new technologies such as in-mold assembly and robotics, and every day, the company looks for ways to increase productivity and agility to better meet the needs of its customers.

Certifications

- ITAR registration

- Certified GREEN Manufacturer

- ISO 13485:2016

- FDA California Device Manufacturing License

Quality Assurance & Control Systems

At Wright, our dedicated quality assurance team ensures that every product meets client standards and relevant regulations. Our commitment to quality is demonstrated by numerous awards and certifications, including our status as an ISO 9001 and ISO 13485 Certified Injection Molder.

Advanced Inspection Capabilities:

- Vision Systems and Coordinate Measurement Machines (CMM): For multi-sensor measurement during inspections

- Optical Comparators: Equipped with 16-inch screens

- Calibrated Surface Plates

- Spectrometers: For precise color shade measurement

- Melt Flow Testers

- CFM Airflow Indicators: Essential for cleanroom applications

- Gram Scales, Microscopes, Gauge Blocks, Gauge Pins, and Digital Calipers

- 3D Optical Profilometers

- Complete First Article Inspection (FAI), in-process inspections, final inspections, and production part approval processes (PPAP)

- Advanced Quality Planning

- Process Validations: Including IQ, OQ, PQ

We customize our quality control services to meet customer needs. These systems support real-time inspections throughout the process, ensuring consistent control, reliability, and repeatability. We emphasize early detection and rectification of quality issues to reduce scrap, downtime, and costs.

Industries Served

Medical

ISO 13485:2016 certified, Wright is poised to meet the exacting quality standards and precise demands of the medical supply industry.

The Santa Rosa facility features clean environment room molding, assembly, and packing equipment, and Wright’s expertise with insert and over-molding is ideal for designing and manufacturing geometrically complex medical parts.

Wright’s specialized quality assurance team can provide tooling, process validation, reports, and statistical analysis to meet custom qualification protocol for medical customers.

Precision Industrial

Wright has considerable experience processing engineering-grade materials for the electronics industry, including ESD coating and LCP and filled materials for shielding. Its expert processing and exterior embellishments give a superior look to products’ enclosures, two-shot logos, and other features, and Wright also makes products for inside assemblies including subassemblies and industrial components.

Defense & Military

ITAR registered, Wright has proven that it can meet the production and quality standards required by the Department of Defense, the military, and the government.

Wright performs Failure Mode and Effects Analysis (FMEA) on all key manufacturing processes, and it produces parts that address these challenges facing the defense industry:

- Lighter and faster components for missile applications

- Maintenance of structural integrity in a variety of environments

- Requirement for state-of-the-art manufacturing solutions

- Need for highly engineered materials such as PEEK